Packaged With Care

Packaged With Care

Through research, education and collaboration, MSU has become a leader in sustainable packaging.

November 20, 2023Attending MSU’s School of Packaging in the mid-1980s and then into her early professional years, Beth Romano, ’88, doesn’t recall the word “sustainability” coming up often, if at all.

That, of course, was before global warming became an international issue, corporate social responsibility emerged a business necessity and packaging ceased being considered solely in utilitarian terms.

These days, Romano, a consumer goods product manager at Huhtamaki, a century-old global packaging company headquartered in Finland, cannot escape sustainability. It drives brainstorming sessions with colleagues on Huhtamaki’s engineering, design and manufacturing teams. It hovers over daily conversations with the clients she serves in the food industry. It informs how Huhtamaki’s facilities operate and how the company introduces its products to the marketplace.

“Priority No. 1 one remains safety, but sustainability is an awfully close second,” Romano said. “It drives all of our innovation. We’re constantly looking for ways to make our products more sustainable.”

In an increasingly environmentally minded world, sustainable packaging is a significant issue—a reality propelled by consumer preferences, swelling regulatory attention and packaging’s visibility and ubiquity in daily life. We’re talking about everything from restaurant takeout containers and toothpaste tubes to corrugated shipping boxes and bags of dog food.

“Packaging might only be a small piece in the entire scope of global warming, but it’s a visible one,” Romano said. “Packaging is something we all rely on and touch daily.”

To Romano’s point, a 2020 study from McKinsey found more than half of U.S. consumers were highly concerned about the environmental impact of packaging, from the use of natural resources and waste to carbon footprints. Meanwhile, Trivium Packaging reported in its 2022 Global Buying Green Report that 57% of consumers were “less likely” to buy products in harmful packaging.

With packaging being an inescapable necessity for modern society, sustainable options are viewed as vital to business and environmental interests, and something the world needs to address. At MSU’s School of Packaging in the College of Agriculture and Natural Resources, one of the nation’s foremost packaging science leaders, an enterprising collective is helping to push sustainable packaging forward through research, education and collaboration.

Inquisitive and Innovative

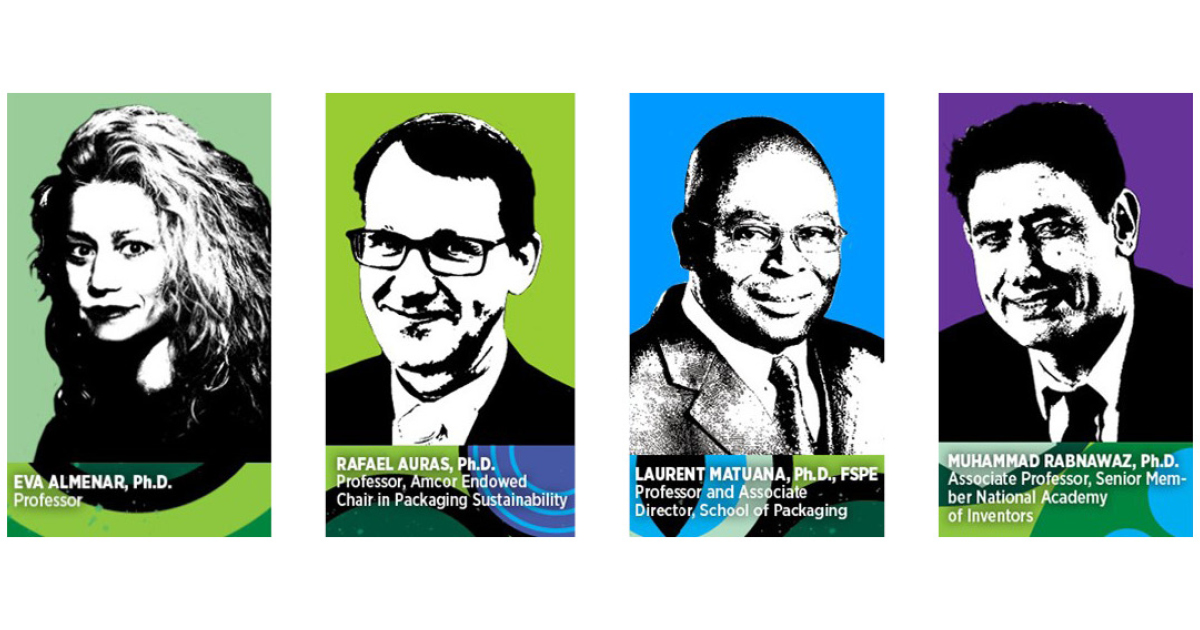

At MSU, researchers are tackling one of the packaging world’s peskiest problems, that is the use of multi-layered plastic common in food storage like potato chip bags and juice boxes. Today, nearly one-third of plastic packaging consists of multiple layers. As each layer holds and provides its own properties, recycling is complicated, explains School of Packaging Associate Professor Muhammad Rabnawaz. Most often, this multi-layered packaging is tossed in a landfill or torched, neither being an environmentally kind result.

Spurred by a $1.7 million grant from the U.S. Department of Energy, Rabnawaz and his Sustainable Materials Group, which includes fellow School of Packaging faculty, 10 graduate and postdoctoral students, research staff, and select undergraduates, are working on packaging that reduces layers and increases recyclability.

In parallel with Rabnawaz’s efforts, Laurent Matuana, professor and associate director of the School of Packaging, is leading efforts to develop an innovative mono-material–a package with one plastic layer—to similarly reduce the environmental challenges of multi-layered packaging and improve recycling capabilities. In one particularly novel project, Matuana is extracting cellulose nanomaterial from trees and adding it into plastics.

“This improves the barrier performance of plastics and reduces the need for multi-layered packaging,” Matuana said.

Utilizing her background and experience in food, material science and packaging, Professor Eva Almenar’s research team is developing packaging materials made from renewable feedstock that they then validate using food and mimicking current supply chain conditions. Almenar’s team is also conducting research to understand packaging’s role in food waste, including shelf-life studies and the interface between consumers and packaging.

Other MSU researchers are seeking more environmentally responsible end-of-life solutions for packaging, especially plastics that harm wildlife, release toxic chemicals and contaminate the food chain.

As research advances, some faculty are then transferring their innovations into the marketplace. Research led by Rabnawaz, who was inducted into the National Academy of Inventors in June 2023, has already ignited two different promising startups: Scops is looking to commercialize paper-based technologies as a replacement for single-use plastics through economical and ecofriendly coatings, while Polyplastic Technologies aims to simplify plastic recycling.

“I honestly had no idea this world could be so exciting and impactful,” said Rabnawaz, a polymer chemist by trade who became increasingly interested in sustainable packaging upon arriving at MSU in 2016. “The more I learned about packaging, the more passionate I became and the more ambitious my research goals to do great things in this field.”

If sustainable packaging is to become a far-reaching reality, innovation spurred by ambitious academic research will play a key role in the development of new materials and methods that are financially feasible and performance oriented.

“Industry alone cannot do it,” Rabnawaz said.

Education and Thought Leadership

Ask professor Rafael Auras about the most energizing part of his work, and the School of Packaging faculty member doesn’t hesitate to offer a sharp answer: mentoring the next generation of packaging professionals.

“There’s such satisfaction when our students and alumni are successful in industry and making meaningful changes,” Auras said.

Auras values his time amongst students. He not only oversees a research group of undergraduate and graduate students interested in sustainable packaging systems, lifecycle assessment, packaging waste, and biodegradable and compostable polymers, but also teaches undergraduate and graduate-level courses in the development of sustainable packaging.

“We need packaging for modern society–it’s necessary for protection, containment and communication–and I want to give students the tools and skills they need to create quality packaging that can also be graded environmentally with the lowest possible impact,” said Auras, who wrote “Life Cycle of Sustainable Packaging: From Design to End of Life” with co-author and MSU School of Packaging Professor Emeritus Susan Selke.

Rabnawaz, meanwhile, leverages his research to enliven the courses he teaches, including an undergraduate class on packaging with plastics as well as graduate-level courses on the stability and recyclability of packaging materials and advanced polymer synthesis.

Recognizing the preparedness of MSU Packaging students to contribute to sustainability-focused goals, packaging industry players hustle to hire graduates and employ students as interns. At Huhtamaki, Romano reels off a list of MSU alums working in different areas of the company, from the firm’s technology and development group to its manufacturing facilities.

“In the industry, there’s wide awareness of how Michigan State is leading in the education and development of sustainable packaging,” Romano said.

That leadership extends beyond MSU’s classrooms and labs. MSU School of Packaging Director Matthew Daum, for instance, has participated in Huhtamaki’s “Think Circle” panels exploring issues, challenges and opportunities in packaging sustainability and circularity, while Rabnawaz leads two different monthlong online courses for industry personnel each year. Both courses attract an international roster of participants.

“That diversity is important because packaging is a global issue,” Rabnawaz said. “After all, the one commonality we all have is the earth we live on.”

Purpose-driven Collaboration

With global warming concerns intensifying and the amount of packaging produced worldwide accelerating, especially in developing countries, sustainable packaging has gained heightened attention among consumers and legislative bodies, both of which continue pushing industry to inject sustainability into their organizational agendas. Rabnawaz calls innovation and earnest collaboration between academia and industry critical to achieve zero-waste packaging that hits environmental, performance and cost targets.

“All three need to work in tandem for sustainable packaging to be successful,” Rabnawaz said.

To that end, MSU has emerged a supportive ally to various stakeholder groups.

Auras, for instance, is advising domestic growers of heavily exported specialty crops like walnuts, mangoes and cherries on the shifting regulatory environment while also helping them prepare more sustainable packaging options. In addition, he has teamed with government agencies such as the U.S. Department of Agriculture (USDA) to create more sustainable packaging solutions for different regions of the world.

“We need more development and resources to further support societies around the globe and balance that with systems that can be more circular,” Auras said.

Matuana is also collaborating with the USDA, specifically its Forest Products Laboratory in Madison, Wisconsin, as well as the U.S. Endowment for Forestry and Communities to commercialize his cellulose technology for sustainable packaging. As Matuana’s solution can be incorporated using conventional plastic processing methods, industry players can more easily implement it.

Packaging Career Fair.

“It doesn’t require investment in new equipment, which makes it something accessible and scalable,” Matuana said. “To push sustainable packaging forward, we need performance of alternative packaging to happen at equal cost.”

For Romano, who is surrounded by talk of sustainability on packaging’s front lines, the research, education and collaboration MSU delivers remains paramount to helping businesses like hers move toward more sustainable packaging that simultaneously supports businesses and the environment.

“Sustainability comes up regularly in conversations because our customers also have their own sustainability goals,” Romano said. “There might not have been extensive talk about sustainable packaging 30 years ago, but it’s here in a big way today.”

Illustrations by Tracy Walker

Contributing Writer(s): Daniel P. Smith